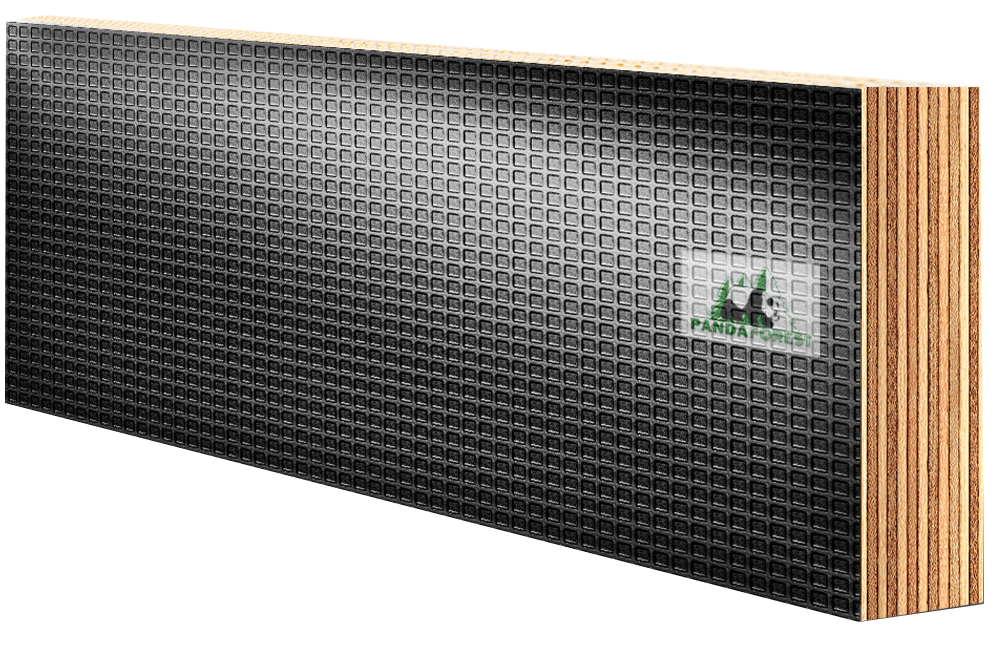

UV Chipboard | UV Coated Polish Chip Board

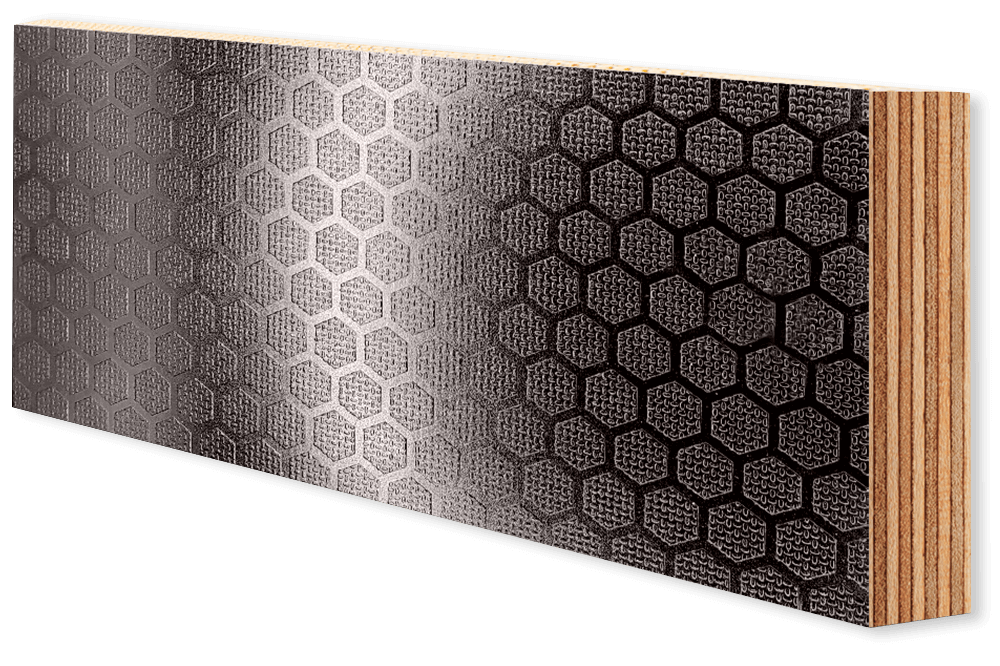

Anti-Skid

Full Birch

Eco-Friendly

Custom

Bonding

Deep penetration, locking each layer of veneer. Special custom-made phenolic adhesives cross-bonded weather resistant glueing according to EN 314-2 / class 6.

FEATURES & BENEFITS

◎ Slip-resistant and Wear resistant surface.

◎ Excellent strength and durability.

◎ Stable mechanical properties.

◎ Can be customized to your needs sharps.

◎ Economical and environmentally friendly.

◎ Support FSC and PEFC legally harvested resources.

◎ Support OEM/ ODM service.

END USE

◎ Vans Floor

◎ Trailers Floor

◎ Construction scaffolding

◎ Stages, terraces

◎ Sports fields and facilities

◎ Playground structures and equipment

◎ DIY

Face and Back

PADANforest - Antislip Trans plywood surface available in five common colors for choose – black, brown, grey, red and blue. Antislip coating density 220g/m2,can be made into single-sided anti-slip or double-sided anti-slip. Wear resistance value from 800 R to 1500 R (EN 438-2) depending on the coating.

Specifications

| Grade | Size | Layer up | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | ||||||

| AA | 1220x2440x6mm | /-/ | 11.2 | Chipboard | 125 or 155 | ||||||

| AA | 1220x2440x9mm | /-/ | 16.5 | Chipboard | 85 or 100 | ||||||

| AA | 1220x2440x11mm | /-/ | 20.5 | Chipboard | 65 or 75 | ||||||

| AA | 1220x2440x12mm | /-/ | 22.5 | Chipboard | 65 or 75 | ||||||

| AA | 1220x2440x15mm | /-/ | 28 | Chipboard | 45 or 60 | ||||||

| AA | 1220x2440x18mm | /-/ | 33.5 | Chipboard | 43 or 50 | ||||||

| AA | 1220x2440x21mm | /-/ | 39.5 | Chipboard | 37 or 45 | ||||||

| AA | 1220x2440x25mm | /-/ | 46.5 | Chipboard | 31 or 37 | ||||||

| AA | 1220x2440x28mm | /-/ | 52.5 | Chipboard | 27 or 32 |

| Finish thickness dry:1.0 – 1.5 mil | |||||||||||

| Layer up:Cross-oriented | |||||||||||

| Moisture Content:8% – 15% (at time of despatch) | |||||||||||

| Dimensional Tolerances:±0.3mm | |||||||||||

| Straightness:±1.5mm | |||||||||||

| Density:650 kg/m³ (approximately) | |||||||||||

| Machinability:Excellent | |||||||||||

| VOC Emissions :None | |||||||||||

| Finish:Unsanded faces, sanding / T&G / Edge banding | |||||||||||

| Branding:Each pallet of PANDAFOREST plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards | |||||||||||

| Storage:Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | |||||||||||

| Source:Plantation timber |

-

Design Eveything

-

Technology Support